Aluminum Foundry features you can learn in a quick read

Wiki Article

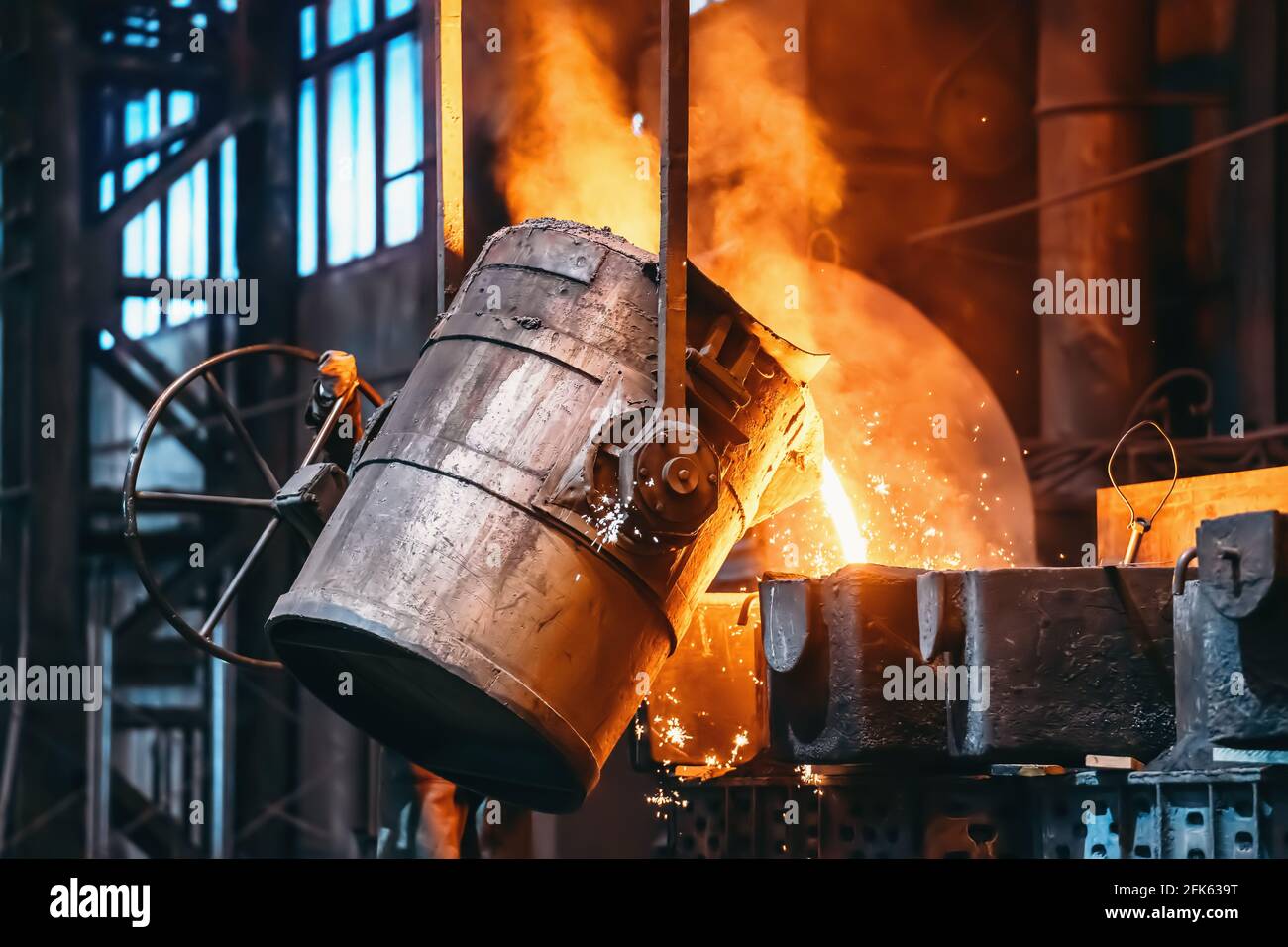

Discovering the Essential Functions and Benefits of Steel Foundries

Steel shops offer an important function in the manufacturing landscape. They change basic materials into precise steel items for various markets. This process includes specialized techniques that ensure high quality and efficiency. The financial effects are significant, impacting neighborhood neighborhoods and job markets. As innovation progresses, so do the methods within the industry. Recognizing these characteristics exposes much concerning the future of manufacturing and its role in sustainability. What lies ahead for steel foundries?The Function of Metal Factories in Manufacturing

Steel shops play a crucial duty in the manufacturing market by transforming raw products right into useful steel products. These facilities specialize in melting and spreading metals, using a selection of methods to develop components that serve multiple industries, consisting of auto, aerospace, and construction. By transforming raw metal ores, scrap steel, and alloys into exact sizes and shapes, shops make it possible for manufacturers to produce top quality products customized to details applications.Metal factories add significantly to the economic climate by cultivating and offering work innovation in metalworking technologies. They often purchase r & d to enhance efficiency and sustainability, decreasing waste and power usage during manufacturing processes. The capacity to create complex geometries not just satisfies design needs however also boosts general product efficiency. Essentially, steel factories work as a crucial web link in the supply chain, guaranteeing the availability of vital metal parts for a myriad of applications in contemporary manufacturing.

Necessary Processes Entailed in Metal Casting

In the procedure of transforming resources into ended up products, steel casting includes several crucial procedures that protect the manufacturing of premium components. The procedure starts with the preparation of molten steel, which frequently entails melting raw products in a furnace. When the steel reaches the preferred temperature level, it is poured right into a mold and mildew shaped to develop the last item.Cooling adheres to, where the molten metal solidifies within the mold, tackling its new form. After adequate cooling, the mold is gotten rid of, revealing the actors component. This is commonly adhered to by finishing processes, including machining, to accomplish specific measurements and surface quality. Furthermore, examinations are conducted to establish that the spreadings fulfill defined standards and tolerances. These vital procedures highlight the detailed nature of steel spreading, stressing the pivotal role that each step plays in producing long lasting and trustworthy steel items.

Kinds Of Metals Frequently Made Use Of in Shops

While different steels can be used in factories, a number of stick out because of their distinct properties and viability for details applications. Iron, specifically in the kind of actors iron, is renowned for its stamina, sturdiness, and outstanding casting characteristics, making it ideal for equipment and vehicle components. Aluminum is preferred for its light-weight nature and resistance to rust, frequently used in aerospace and transport markets. Copper alloys, such as bronze and brass, are chosen for their remarkable conductivity and aesthetic allure, typically found in electric elements and decorative things. Steel, specifically carbon steel, is valued for its durability and flexibility, extensively utilized in construction and production. Magnesium is appreciated for its reduced density and high strength-to-weight proportion, making it a favored selection in applications needing light-weight materials. Each of these steels uses unique benefits that accommodate the varied needs of numerous industries.Top Quality Control Measures in Steel Shops

Quality control actions in metal factories are essential for making sure item stability and conformity with sector standards (Aluminum Foundry). Different examination techniques are utilized to analyze the homes of actors steels, while adherence to established requirements and qualifications strengthens quality control. This systematic method not only improves functional performance but also builds client depend on in the last itemsInspection Techniques Overview

Effective evaluation methods are crucial for keeping high criteria in steel shops, as they assure that each item fulfills defined resistances and efficiency demands. Different techniques are utilized to examine the high quality of spreadings, including visual evaluations, dimensional checks, and non-destructive testing (NDT) Visual assessments permit operators to recognize surface issues such as cracks or additions, while dimensional checks confirm that parts comply with design specifications. NDT techniques, such as radiographic and ultrasonic screening, give much deeper understandings into internal flaws without harming the item. In addition, automatic evaluation systems are increasingly used to boost accuracy and efficiency. With each other, these assessment strategies play a significant role in safeguarding item integrity and client fulfillment within the competitive landscape of steel factories.Specifications and Certifications

In the domain of steel foundries, adherence to developed requirements and certifications offers as a foundation for top quality control procedures. These standards, such as ISO 9001 and ASTM, supply frameworks that ensure consistent item quality and dependability. Certification processes entail extensive analyses, including audits and assessments, verifying that factories fulfill particular efficiency standards. Compliance with these criteria not only improves item integrity however additionally fosters client trust fund and complete satisfaction. In addition, certification can open brand-new markets, as many industries need conformity for purchase. By executing these high quality control actions, metal foundries can lessen issues, optimize manufacturing processes, and keep an one-upmanship in the industry. Generally, criteria and qualifications play a critical function in ensuring the success and sustainability of steel shops.Technologies and Technologies in Shop Operations

As the demand for precision and efficiency in metal casting continues to grow, foundries are increasingly adopting developments and technologies that improve their operations. Automation plays a critical function, with robotic systems improving processes such as mold and mildew handling and spreading. This not just lowers labor prices yet additionally lessens human error, resulting in boosted item high quality.Furthermore, developments in computer-aided design (CAD) and simulation software enable shops to maximize styles before production, enabling faster turn-around times. Integrating 3D printing innovation for creating mold and mildews and cores even more accelerates manufacturing and permits complicated geometries that traditional approaches can not accomplish.

The integration of information analytics and the Web of Things (IoT) supplies real-time monitoring of Metal Casting tools and processes, boosting predictive upkeep and operational efficiency. These advancements collectively add to a more receptive, agile, and affordable foundry setting, positioning them well to satisfy evolving market needs.

Financial Effect of Steel Foundries on Neighborhood Communities

The innovations in technology within steel shops not only boost production abilities yet also substantially influence regional economic situations. Metal factories work as a significant resource of work, providing tasks for skilled workers and adding to the financial stability of their regions (Metal Foundry). These facilities commonly stimulate local services, as they call for a series of services and materials, from raw products to transport and logistics. The presence of a metal foundry can likewise draw in relevant sectors, fostering a network of providers and supporting services that prosper in distance to producing centersFoundries contribute to the tax obligation base, generating revenue for local federal governments that can be made use of for public solutions and framework renovations. The financial causal sequence prolongs to neighborhood advancement, as foundries frequently take part in local initiatives and assistance labor force training programs. Generally, metal factories play a vital role in bolstering the financial landscape of their areas, making sure growth and sustainability.

Sustainability Practices in the Metal Factory Sector

The steel factory industry is increasingly taking on sustainability techniques to minimize its environmental footprint. Trick methods include reusing steel scrap, executing energy performance procedures, and utilizing eco-friendly spreading processes. These campaigns not just contribute to source conservation but additionally improve the sector's general sustainability profile.Recycling Steel Scrap

Recycling steel scrap stands as a foundation of sustainability techniques within the metal foundry market. This process not just conserves all-natural resources yet also substantially minimizes landfill waste. By recovering scrap metal, factories can reduce the requirement for virgin materials, lessening environmental effect and power consumption connected with mining and extraction. The recycling of steel scrap promotes a round economy, where materials are recycled and repurposed, creating a much more lasting production cycle. Factories usually execute innovative sorting and handling technologies to improve reusing efficiency, guaranteeing high-quality output. As the market significantly focuses on environmentally friendly methods, the recycling of steel scrap remains a vital element, advertising both financial viability and environmental stewardship for future generations.Energy Effectiveness Procedures

Sustainability in the steel shop sector expands beyond recycling practices to encompass energy effectiveness procedures. Factories are significantly taking on modern technologies that reduce energy consumption during metal production and spreading. Implementing advanced melting techniques, such as induction melting, allows for even more precise temperature level control and lowered power waste. In addition, maximizing heater procedures with warm healing systems captures and reuses excess heat, especially lowering total power requirements. The combination of energy-efficient lighting and automation also boosts functional effectiveness. By buying these energy efficiency actions, foundries not only decrease their carbon footprint yet additionally recognize expense savings, adding to a much more lasting and financially practical industry. Taking on such practices is essential for resolving and fulfilling governing standards growing environmental problems.Eco-Friendly Casting Processes

While typical spreading approaches have offered the metal factory industry for years, green spreading processes are now acquiring importance as a crucial component of lasting manufacturing. These ingenious methods focus on the decrease of waste, energy consumption, and damaging exhausts. Many shops are embracing recyclable materials and water-based coatings, lessening environmental effect. Additionally, innovations in 3D printing modern technology facilitate extra efficient styles, reducing the demand for substantial material use. Closed-loop systems are likewise being implemented, permitting the recycling of metals and various other spin-offs. By welcoming these environmentally friendly techniques, steel factories not only improve their operational performance but also add to the worldwide effort towards sustainability, aligning with increasing consumer need for ecologically liable products.Regularly Asked Questions

What Precaution Are Implemented in Steel Foundries?

Security measures in metal shops include personal protective tools, correct ventilation systems, normal security training, danger communication, emergency action protocols, and routine equipment upkeep to minimize risks related to dangerous products and high temperatures.Exactly How Do Factories Deal With Hazardous Materials?

What Prevail Profession Opportunities in Metal Foundries?

Typical profession opportunities in steel factories include duties such as shop professional, melting operator, quality assurance inspector, upkeep designer, and production manager, each adding to the effective procedure and result of steel spreading processes.

Exactly How Do Foundries Manage Waste and Recycling?

Factories take care of waste and recycling via organized processes, including the collection of scrap metal, reusing materials, and executing eco-friendly techniques (Aluminum Foundry). These methods aid lessen ecological impact while promoting resource effectiveness within the sectorWhat Are the Ecological Regulations for Metal Foundries?

Steel foundries play an important duty in the production field by changing raw materials into useful steel products. Quality control steps in steel factories are necessary for ensuring item integrity and conformity with sector standards. By executing these quality control procedures, metal shops can lessen defects, optimize production procedures, and maintain a competitive side in the market. Recycling steel scrap stands as a keystone of sustainability techniques within the steel shop market. While standard spreading approaches have actually served the metal factory sector for decades, environment-friendly spreading processes are now obtaining prominence as a crucial element of lasting production.

Report this wiki page